Yibo Ai received the B.S. degree, M.S. degree and Ph.D. degree in control science and engineering from University of Science and Technology Beijing, Beijing, China, in 2004, 2007 and 2018, respectively. Her research interest includes artificial intelligence, big data fusion, complex system modeling, nondestructive detection, system reliability analysis and remaining life prediction. She has been engaged in the application on high speed train gear transmission system, dynamic object trajectory characteristics analysis, biometrics feature recognition and multi-levels system service safety assessment. She has presided over and participated as the main member a number of National Science Foundation China, National Key Research and Development Program Project and other projects in China, and won the second prize of Beijing education teaching achievement award.

1. National Key Research and Development Program Project, 400km/h High-Speed Train Wheel Full- Chain Applicability Evaluation Standard System, 2023YFA1609204 - 02, 2023-2027

2. Enterprise Research Project, Research on Human Pose and Behavior Analysis Based on Artificial Intelligence Video Analysis Model and Server Software Development, 2024-2028

3. Key Plan Project of HBIS Group, Research on Continuous Casting Process Quality Improvement Based on Hybrid Modeling and Intelligent Optimization, 2023-0370, 2022-2024

4. Enterprise Research Project, Research and Development of Visual Detection Model for Characteristic Markers in the Steel Industry Based on Deep Learning, 2023-2024

5. Innovation Team Project of Southern Marine Science and Engineering Guangdong Laboratory, Cross-Scale Service Safety Evaluation and Digital Model of Marine Titanium Alloy Materials and Equipment, 2021-2023

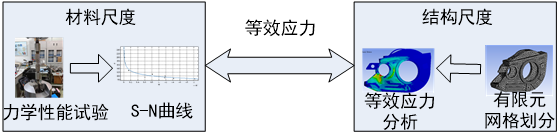

- Contribution 1:Complex System Cross-scale Life Prediction and Reliability Analysis: A "material scale—structure scale" cross-scale correlation and decision method for life prediction of gearbox shell has been proposed. The equivalent stress has been used to connect the structure scale finite element and material scale. The fuzzy decision making method has been applied to do the cross-scale decision between simulation result and inspection result of key structure locations in sample bench test.

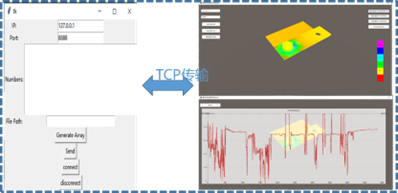

- Contribution 2: Material Service Performance Prediction Based on Digital Twin Technology: Aiming at the problem that environmental sequence parameters caused by uncertainties and randomness in the material failure process cannot be corresponded to the mechanism model, digital twin technology is introduced. Monitoring data is used to update failure prediction data, realizing a point to point real time visualization process of multi-dimensional information of the material failure process in the digital twin model.

1. Ai Yibo, Wang Fan, Sun Chang, Zhang Weidong. Performance Degradation Analysis and Life Prediction of the Fatigue Damage Process of High Strength Aluminum Alloy Using Acoustic Emission[J]. Journal of Nondestructive Evaluation. 2021,40(43):1 - 12.

2. Ai Y, Ma N, Zhang T, et al. A new mean value of failure criteria updated compensation method based on heuristic MAP estimation for tensile damage diagnosis of high - strength aluminum alloy[J]. Engineering Failure Analysis, 2022, 136: 105997.

3. Yibo Ai, Peng Cui, Yuanyuan Li, Weidong Zhang. Research on reliability allocation strategy for gear transmission system of high - speed train[J]. Eksploatacja i Niezawodnosc – Maintenance and Reliability, 2022, 24(3): 574 - 582.

4. Ai Y, Yang Z, Que H et al. Finite Element Simulation and Fatigue Damage Analysis of High - Speed Train Gearbox Shell Based on Structure and Material Cross - Scale Correlation. J Fail. Anal. and Preven. 2022, 22:1215–1228.

5. Ai Y, Zhang W, Huang S, et al. A Cross - layer Energy Control Strategy for Indoor Wireless Meter Reading Systems[J]. Ad - hoc & sensor wireless networks, 2022, 53(1 - 2): 29 - 57.

6. Zhang T, Ai Y, Tian K, Zhou J, Zhang W. “A fast temperature rise identification method based on an adaptive particle filter”. International Journal of Advanced Manufacturing Technology, 2018(1-4):1-19.

7. Sun C , Ai Y , Wang S , et al. Mask-guided SSD for small-object detection[J]. Applied Intelligence, 2021, 51(20):1-12.

8. Xie Z, Ai Y, Zhang W, et al. Deep Recurrent Neural Network Architecture of High Order lndirect lntegration Method[J]. Neural Processing Letters, 2022, 54:1233–1253.

9. Wang F, Ai Y, Zhang Weidong. Detection of early dangerous state in deep water of indoor swimming pool based on surveillance video. Signal, Image and Video Processing, 2022,16: 29–37.

10. Zhang T, Liu J, Ai Y, Zhang W. Multi-layer additive tensor decomposition of infrared video for titanium alloy tensile testing[J]. Engineering Applications of Artificial Intelligence, 2023, 124: 106552.

1. Ai Yibo, Zhang Weidong, Li Shuaihang. A Grain Recognition Method and Device for EBSD Metallographic Images. Chinese Invention Patent, 202110297266.7

2. Zhang Weidong, Ai Yibo, Sun Chang, Lv Tao, Zhang Xiwen. A Fatigue Loading Test and Fatigue Damage Non - Destructive Testing and Analysis Method for Metal Materials. Chinese Invention Patent, 201510059474.8

3. Zhang Weidong, Ai Yibo, Sun Chang, Wang Nan. A Detection Method and Analysis Method for the Evolution of Internal Defects during the Fatigue Process of Metal Castings. Chinese Invention Patent, 201510009344.3

1. 2018: Second Prize of Beijing Education and Teaching Achievement, Ranked 3rd

2. 2020: Excellence Award of the 5th China Innovation Challenge, Ranked 1st

3. 2021: Second Prize of Beijing University of Science and Technology Education and Teaching Achievement, Ranked 2nd

4. 2021: Second Prize for Outstanding Instructor in the Discipline Competition of the Beijing Competition of the iCAN Innovation and Entrepreneurship Competition, Ranked 1st

5. 2021: Excellence Award of the 6th China Innovation Challenge, Ranked 1st

6. 2024: Second Prize of Beijing University of Science and Technology Education and Teaching Achievement, Ranked 2nd.

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026